The usage of powder metallurgy in car

2018-01-24

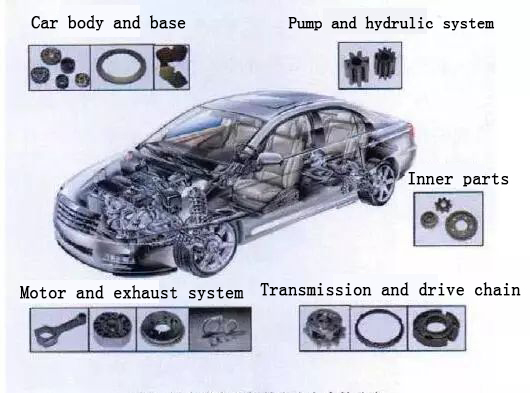

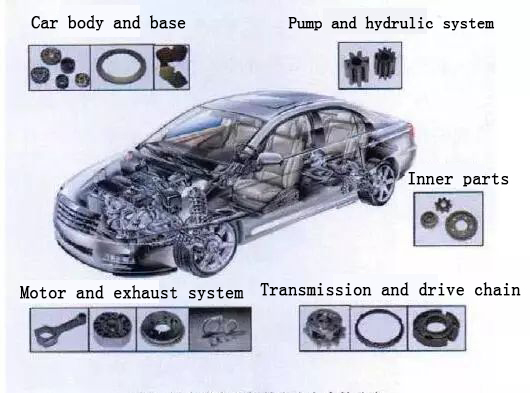

At present, the average usage of powder metallurgy products per vehicle in Europe is 14kg, Japan is 9kg, the United States has reached 19.5kg or above, and it is estimated that it may reach 22kg in the next few years. At present, China's average consumption of powder metallurgy products per vehicle is only 5 ~ 6kg, taking into account the factors of energy saving and emission reduction, the domestic enterprises in the future will be more use of powder metallurgy technology to produce auto parts. Powder metallurgy parts in the distribution of the car shown below. Among them, there are shock absorber parts, guides, pistons and low-seat seats in the chassis of the automobile; there are ABS sensors and brake pads in the braking system; the key parts of the pump parts are fuel pump, oil pump and key components in the transmission pump; In the catheter, seat, connecting rod, bearing seat, variable valve timing system (VVT) key components and exhaust pipe bearings; transmission has a synchronous hub and planetary gear and other components. With the improvement of automobile energy-saving and emission reduction requirements, in recent years, VVT parts, variable-displacement pumps and brake vacuum booster pump parts have been developed and applied in a large amount in these three categories of energy saving and emission reduction vehicle parts.

1.VVT powder metallurgy parts

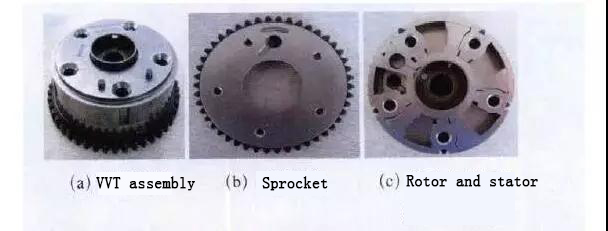

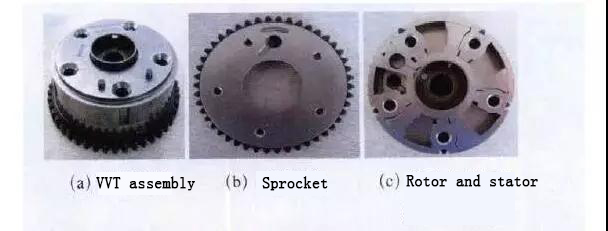

VVT or VCT (Variable Cam Timing System) adjusts the phase of the engine cam through the control and execution system provided, so that the valve opening and closing time changes with the engine speed to improve the charging efficiency , Increase the engine power system. The principle is based on the operation of the engine, adjust the intake and exhaust and valve opening and closing time and angle, so that the amount of air into the best to improve combustion efficiency and reduce emissions. Its advantage is fuel economy, power upgrade. Alfa Romeo first used VVT technology in 1980; for the first time in 1989, Honda used VVT technology with variable valve lift capability; in 2001 BMW first used the VVT technology to replace the traditional throttle in 2001. There are different names for similar technologies, such as Toyota's VVT-i, Honda's VTEC and i-VTEC, Mitsubishi MIVEC, Nissan's CVVT, and European and American VCT's. VVT or VCT system actuators - the core components in the phase sprocket, stator, rotor and end caps are mostly used powder metallurgy process. The promotion of the use of VVT technology is in line with the trend of international automobile technology development, namely energy conservation, miniaturization, light weight and fuel economy. In accordance with the actual detection of a domestic enterprise, displacement of 1.3L economical car, the engine using VVT technology can increase power by 4.6%, saving 18.6%.

2.Powder metallurgy parts in the pump

At present, most of the engine oil pump and automatic transmission oil pump use quantitative oil pump. The quantitative oil pump is generally a variety of structures such as an externally-meshed gear pump, an internal-gear cycloidal pump or a ring gear pump. Quantitative pump, the size of its oil output increases with the engine speed increases, the two linear relationship. In order to ensure the minimum oil output at low speed and the minimum oil pressure at high speed, the oil pump will be designed to be larger, which sets a higher requirement on the layout of the engine compartment. At the same time, the engine at high speed, the excess oil will return from the oil, resulting in increased engine power consumption. The variable pump will be based on engine work, adjust the pressure and oil, so as to achieve the purpose of fuel-efficient. Research data shows that with a fixed displacement oil pump engine, when the speed> 2500r / min, about 50% of the motor oil directly through the relief valve back to the pump into the oil chamber or the oil pan, bringing energy Of the waste; while using variable displacement pumps instead of quantitative pumps can generally save fuel 2% to 5%, CO2 emissions reduced by 1% to 2%. Variable displacement pumps generally have external gear pumps, vane pumps and vane pumps and other types of structures. External gear pump such as the public's EA888 project, one of the gear axial position fixed, the other with a spring axial pressure with the pressure adjustment, when idle gear all meshing, when the speed increases, the pressure pump with With the increase of the compression spring gear meshing part of the shorter, so as to adjust the flow of the pump at any time, the pump gear is manufactured using powder metallurgy process. Vane-type variable displacement pump is mainly composed of a stator, a rotor and a blade. The stator and the rotor are all powder metallurgy parts. Vane variable pump works by adjusting the eccentric pressure to adjust the flow. Vane variable pump principle and the basic vane-type variable pump to adjust the eccentricity to adjust the flow. The structure shown in Figure 5a, in which the vane is a steel, and the vane is connected to the middle sleeve, the outer sleeve, the rotor is the middle of these three are powder metallurgy. 3. Brake power vacuum pump powder metallurgy parts

Vehicles equipped with gasoline engines, because the engine is ignited, so the intake manifold can produce a higher vacuum pressure, vacuum assisted braking system can provide sufficient vacuum source, the current vacuum pumps are mostly connected to the intake manifold Department. In order to meet the high emission and environmental protection requirements designed gasoline direct injection engine, the intake manifold can not provide the same level of vacuum pressure to meet the vacuum brake booster system requirements, the need to install a vacuum pump. For diesel engine driven vehicles, the vacuum pumps are installed to provide a vacuum source because the engine is compression ignited and does not provide the same level of vacuum pressure at the intake manifold. The vacuum pump power is obtained directly from the engine, power through the powder metallurgy joint drive powder metallurgy rotor and then drive the plastic valve plate, the rotor and the pump chamber has a certain amount of eccentricity, the valve plate is rotated to produce a vacuum, the final completion of the system Help move effect. This type of vacuum pump is mainly developed to meet the high-emission gasoline engine and diesel engine, and has played a role in emission reduction.