LINA Two Roll Open Mill

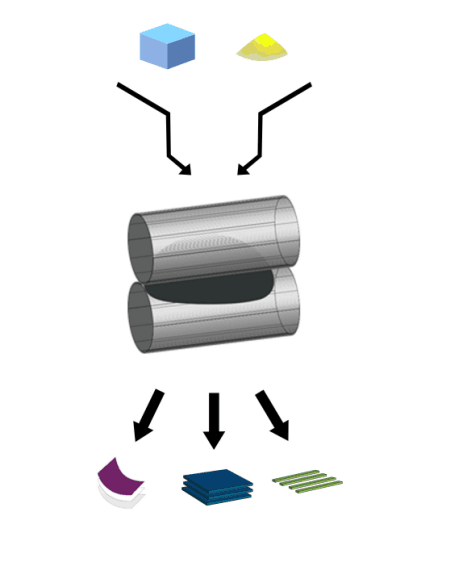

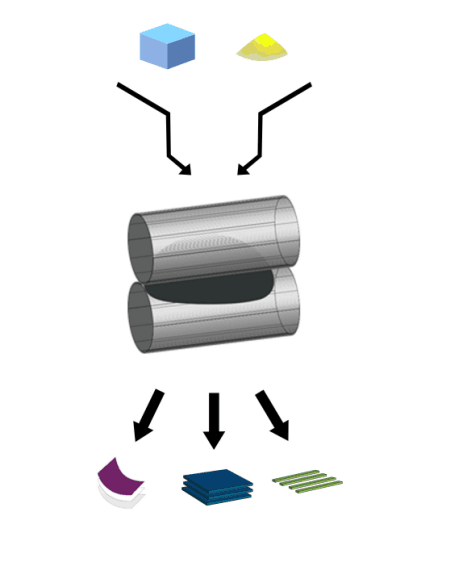

LINA two roll milling machine is suitable for rubber, plastic, elastomer and other polymers. It is easy to operate with low maintenance rate. The roller is made of high quality carbon steel, which is treated by nitriding and the surface is plated by hard chromium, and the holes in the roller ensure the cooling effect and efficiency.

Laboratory and Mass Production Two Roll Open Mill are designed for laboratory tests and large capacity production. LINA open mill can apply to high-tenacity, high-viscosity and high-hardness rubber or plastic compounds etc. Safety is our first priority, our engineers have researched and developed comprehensive safety devices like 360 degrees emergency stop button, reverse braking devices, infrared sensor and ergonomics security devices etc. LINA two roll milling machine`s safety devices have applied the national patents.

Advantage of LINA Two Roll Open Mill

LINA open mill takes the lead in the whole plant equipment planning and formulation technology supporting services and deliveries the [key" to many enterprises` projects have solved various technical obstacles for clients. Our two-roll open mill production line have researched and completed special machines technologies for different industries like environmental or branch of industry and handle the furnishing of compounding facilities to improve automation systems.

Higher cleanness, wearable inner cavity, adjustable rotor speed ratio, temperature control system, PLC intelligent control system and safe devices ensure our machine are used worldwide for the manufacture of rubber and plastic products, sealing profiles, cables, tyre applications and friction linings as well as for special polymer blends and thermoplastic elastomers.

Main features

1. Comprehensive safety devices like 360 degrees emergency stop button, reverse braking devices, infrared sensor and ergonomics security devices etc. LINA two roll milling machine`s safety devices have applied the national patents for protection.

2. LINA two roll open mill roller is made of high quality carbon steel, which is treated by nitriding and the surface is plated hard chromium. And the medium hole of the roller ensures the cooling efficiency.

3. PLC intelligent soft control system is not only easily import or export but also accurately in control and measurement of mixing temperature and ratio.

4. Multifunctional options ensure easier operation and lower maintenance rate. LINA two roll open mill is designed for laboratory and mass production to plasticizing, mixing and performing, Heating system, cooling system or double functions system are available to meet the mixing requirements of a variety of materials and improve flow production efficiency.

| Item | Technical Datum |

| Model | XK-120 | XK-160 | XK-200 | XK-300 | XK-360 | XK-400 | XK-450 | XK-550 | XK-560 |

| Roller diameter | mm | 120*350 | 160*350 | 228*600 | 300*700 | 360*900 | 400*1000 | 450*1200 | 550*1500 | 560*1530 |

| Front roller liner velocity | r/min | 19 | 18 | 16 | 13 | 11 | 11 | 10 | 9 | 8 |

| Roller velocity ratio |

| 1.24 | 1.29 | 1.27 | 1.3 | 1.2-1.3 | 1.2-1.3 | 1.2-1.3 | 1.2-1.35 | 1.3 |

| Max pitch | mm | 0-5 | 0-5 | 0-8 | 0-10 | 10 | 10 | 12 | 16 | 15 |

| Machine output | kg | 0.5-1.5 | 1.5-3 | 6-10 | 10-15 | 15-25 | 20-35 | 30-50 | 50-70 | 50-70 |

| Voltage | V | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Motor power | kw | 5.5 | 5.5/7.5 | 7.5/11 | 15/18.5 | 30 | 45 | 55 | 90/110 | 160 |

| Weight | KG | 800 | 1000 | 1200 | 2500 | 6500 | 8000 | 10000 | 22000 | 22500 |

Functional options

| No. | Function | Description | Please tick (✔) | Price (USD) |

| 1 | Motor-driven and speed-decreasing roll pitch regulation | Improve the work efficiency and the uniformity and consistency of the thickness of the rubber |

|

|

| 2 | Pneumatic cutting device | Cutting the rubber with a settled width |

|

|

| 3 | Cutter distance adjusting device | Ensure the uniformity and accuracy of the width of rubber |

|

|

| 4 | Lifting device for baffle moving | For easy cleaning and higher safety |

|

|

| 5 | Hydraulic device for moving of baffle | Hydraulic movement of baffle can reduce labor intensity and improve safety |

|

|

| 6 | Automatic hydraulic refueling device | Ensure the roller bearing cooling and lubrication of high strength and high saturation |

|

|

| 7 | Automatic Material Stirring Device | Reduce labor intensity and improve safety |

|

|

| 8 | Interval mixing timing reminder | Avoid worker forgetting to remind feeding the small material |

|

|

| 9 | Frequency Converter | Save energy and controllable speed when preforming |

|

|

| 10 | Corrosion proof treatment | The rollers and the periphery of the press plate should be plated with hard chromium or stainless steel |

|

|

| 11 | Customized full-scale safety system | Avoid hidden dangers of production and increase the safety of operators |

|

|