Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

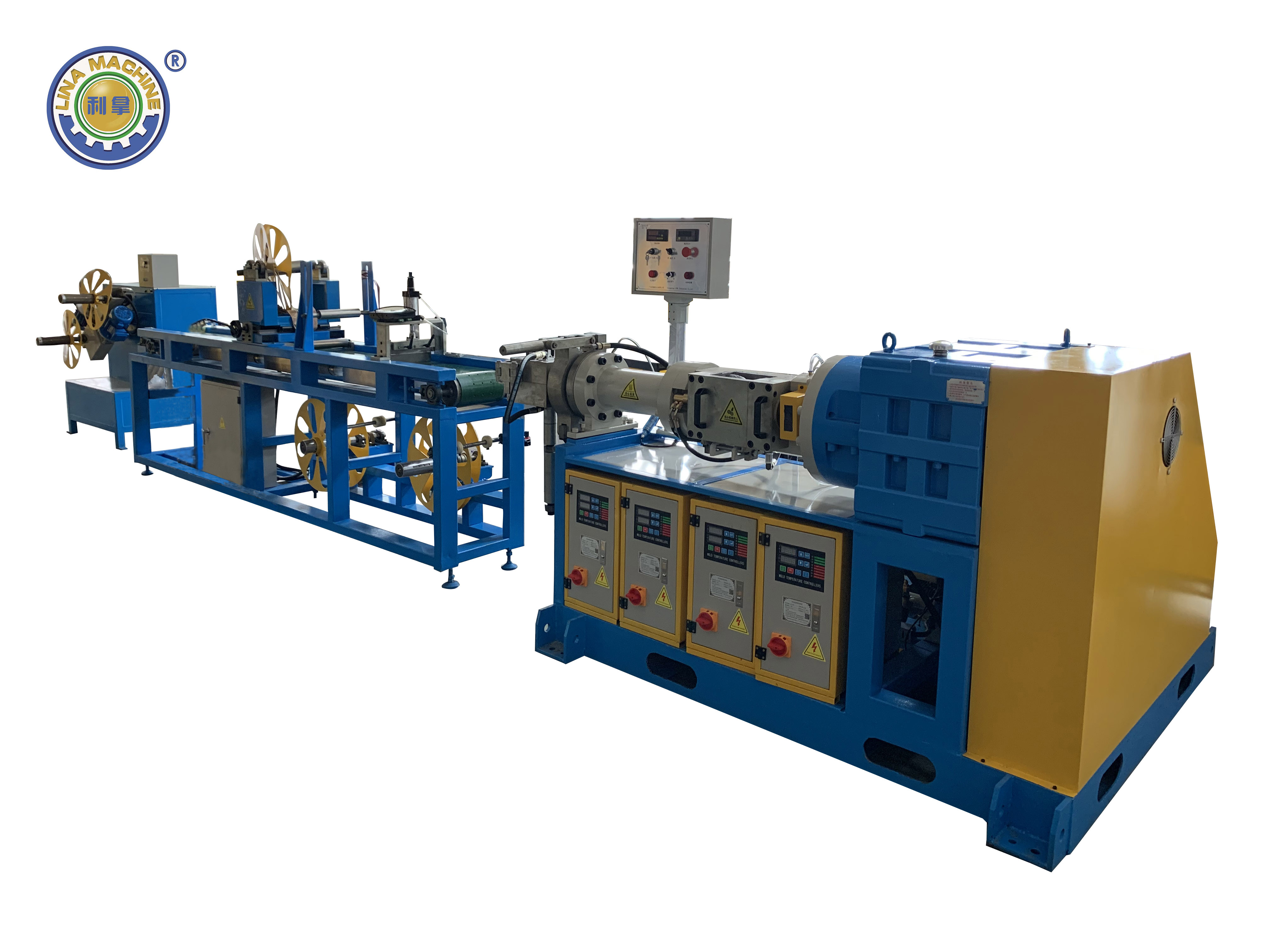

The Rubber Extruder is a basic equipment in the rubber industry and one of the key equipment affecting product quality. It plays a very important role in the production process of tires and rubber products. The development of foreign rubber extruders has experienced plunger extruders, screw-type hot feed extruders, ordinary cold feed extruders, main and auxiliary screw cold feed extruders, cold feed exhaust extrusion Machine, pin cold feed extruder, compound extruder and other stages.

But the situation of the cold feed extruder is quite different. The rubber material fed is both cold and hard, and all kinds of cold hard rubber materials must be extruded by the cold feed extruder itself to achieve its extrusion process requirements. From cold to hot, from hard to soft, and from non-homogenization to homogenization, the processes go through obvious stages of change, and each stage influences each other. When other operating conditions are constant, the temperature of each section of the extruder plays a decisive role in the extrusion process. If the temperature of each section changes, the extrusion speed, extrusion temperature and expansion rate of the extrusion process will all change, causing the extrusion operation to lose stability and seriously affecting the quality of the semi-finished products.

The above is about the importance of the temperature control of the rubber extruder. If you want to know more about our company's dynamics or products, you can consult us. We also sell Dispersion Kneader, Rubber Internal Mixer, Rubber Open Mill, Two Roll Mill, Plastic Granulator and Extrusion Pelletizer.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.